SPECIFICATIONS

After-sales Service Provided: 1 Year

Application: Surface Treatment

Coating color: Customers Demand

Equipment Name: Electrostatic Powder Spraying System

Keywords: Manual powder coating equipment

Product name: Painting Spray Machine Powder Coating Machine

Spraying Guns: Manual Powder Spray Gun

Technology: Electrostatic Powder Spraying Technology

Type: Electrostatic Powder Coating Equipment

Usage: Powder Coating Workpieces

brand name: Onk Vibration suction powder coating machine

coating: Powder coating

core components: Pressure vessel,gun,Powder pump,Control device

dimension(l*w*h): 58*58*80cm

key selling points: Easy to Operate

machine type: Painting Equipment,powder coating machine,powder coating equipment,powder spraying machine

machinery test report: Provided

place of origin: Zhejiang, China

power(w): 80W

substrate: Steel

type: Electroplating Production Line

video outgoing-inspection: Provided

voltage: 110v/240v

warranty: 1 Year

weight (kg): 36

Controller

Wholesale Cheap Gema Optiflex 2b Electrostatic Painting Spray Machine Powder Coating Machine

1) Intelligent 2) Multi-functionvvvv

3)One-key operation for deep corner and Re-coating process

4) Remote HV control by the gun

5) Digital display for all the values

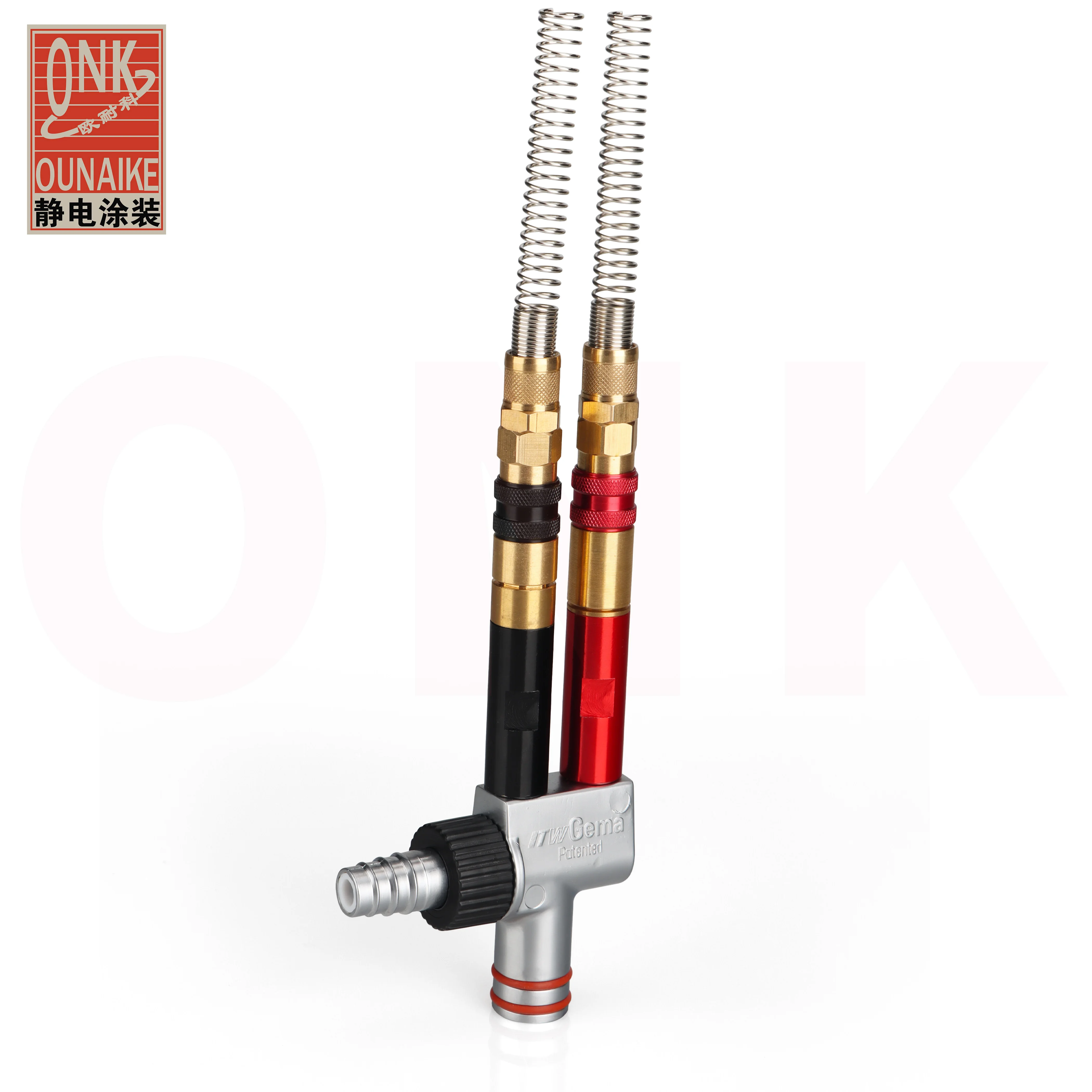

Manual Spraying gun

1)Antistatic wear-resistant material for spray gun

2)Ensures the high voltage and the service life

3)The remote control buttonis at the back of the gun

4)The powder output and program can be adjustable at any time.

Spare parts

Flat nozzle+round nozzle+ powder injector sleeves

Powder pump

1) Insert use pure Teflone material,which was not easy to stick to powder

2)The conductive ring is connected with powder tube

3) To reduce the possibility of the powder adsorbing on the powder pump

4)Reduce the damage of high speed fluidized powder to pump body

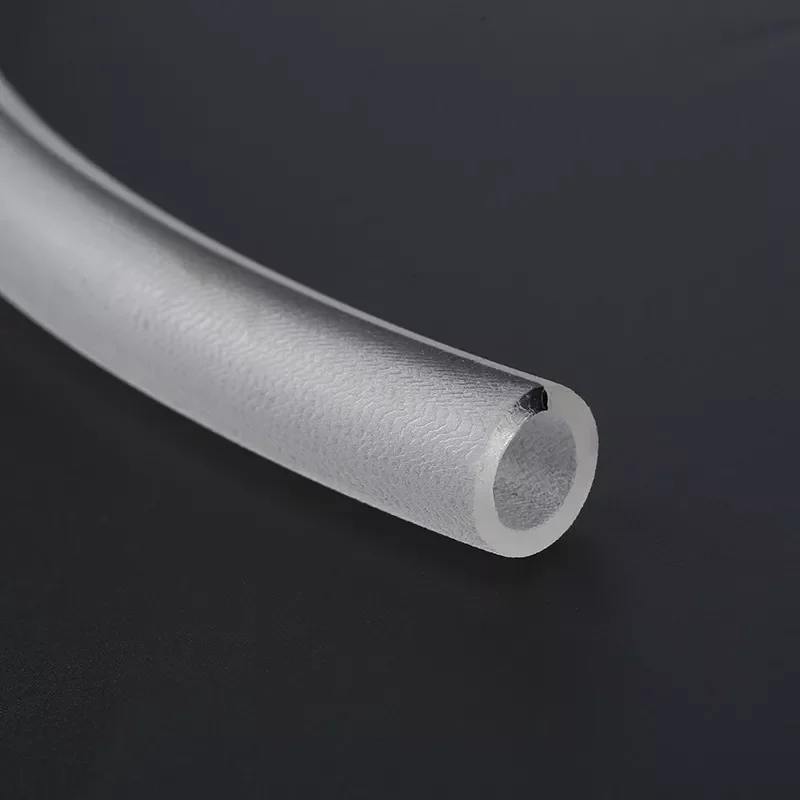

Powder hose

1)High quality rubber material.

2)Good flexibility, can bend at any angle, no creases.

3)Containing grounding wires.

To reduce the possibility of powder adsorb on powder hose.

4)Prolong service life of powder hose.

Powder suction tube

1)Use of high quality aluminum alloy, not easy to deform with long service life.

2)Self- cleaning facilitates color change.

3)Bottomed fluidization ring with the help of the vibrating table.

4)The fluidized ring further fluidization of the powder.

Fluidization effect achieves the best.

No |

Item |

|

1 |

Voltage |

|

2 |

Frenquency |

|

3 |

Input power |

|

4 |

Max. output current |

|

5 |

Output power voltage |

|

6 |

Input Air pressure |

|

7 |

Powder consumption |

|

8 |

Polarity |

|

9 |

Gun weight |

|

10 |

Length of Gun Cable |

|

FAQ

1. Which model should I choose?

It is depend on your actual workpiece, whether it is simple or complicated. We have abundant types with different features to suit various customers requirement.

What's more, we have also have hopper type and box feed type depending on whether you need frequently change powder colors.

2. The machine can work in 110v or 220v?

We exported into more than 80 countries ,so we can supply 110v or 220v working voltage ,when you order you just tell us which you want ,it will be ok.

3. Why some other company supply machine with cheaper prices ?

Different machine function ,different grade parts choosed ,machine coating job quality or Lifetime will be different.

4. How to pay ?

We accept the western union ,bank transfer and paypal payment

5. How to delivery?

By sea for big order ,by courier for small order